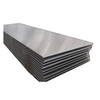

Hot-dip coated with commercially pure aluminum. It is intended principally for applications requiring atmospheric corrosion resistance. Type 2 may ultimately be manufactured into corrugated roofing and siding, grain bins, air conditioner housings and drying ovens.Characteristics:

- Good atmospheric corrosion standard.

- Various coating weights

- Appearance

- Maintenance free

- Highly reflective of solar heat

- Fire resistant.

Coating :

The Aluminized Steel Type 2 coating microstructure is comprised of two layers: an aluminum layer and an underlying hard aluminum-iron inter metallic alloy layer. The alloy arises from interaction of molten, commercially pure aluminum with the steel surface and is the agent that bonds the coating to the substrate. The alloy is an essential part of the coating protection system, supplementing the aluminum layer and providing a second line of defense to ensure long term durability. Control of the alloy layer thickness and thickness uniformity assures the degree of coating formability necessary for corrugated steel pipe manufacture.Applications :

- Storm sewers.

- Freshwater drainage.

- Road culverts.

- Storm water detention.

- Corrugated Roofing/Siding.

- Grain Bins.

- Drying Ovens.

- Air-conditioner condenser housin

| Place of Origin | India |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |

| Elongation | 10% to 60 % |

| Technique |