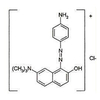

We offer salt free dyes for inkjet and textile printing, which is the end product resulted after removing salt and other impurities. Manufactured using membrane and reverse osmosis technology, these dyes are environment friendly. The removal of salt increases the solubility and fastness of dyes. These dyes are available in different shades as per the requirements of our clients.

Our Company which is one of the leading companies for INKJET - SALT FREE DYES We Produce and Exports Water Base Desalinated Dyestuffs.

Salient Features:

We are process that as comprehensive purification and filtration, which is high purity & that is of critical importance, such as inkjet printing

- Ultra filtration / Reverse Osmosis - Removes Inorganic Salts

- Ion exchange - Improves solubility

- Carbon treatment - Improves surface tension

- Micro filtration - Removes 99.9% of insoluble

- Specialized cartridge filtration (as low as 0.2 micron) - Removes most insoluble.

These are suitable for the formulation of water-based inks due to low electrolyte content, and due to very high solubility.

For salt free Dyes what we are testing in our Laboratory we are explain you as below:

1.ph (1 gm/99 ml water) by ph meter

2.Moisture @135C (LOD) by Kalfisher machine

3.Insoluble (in10%SOIN.Through 0.2 micron filter paper) crucible

4.Chloride contain by Potiotritration

5.Absorbance @nm (10 mg/LD WATER) BY U>V spectrophotometer

6.Solubility (in 10%solnThorughO.2micronfilter paper) Result in second pass Minimum 20 second

7.Surface tension we check in product minimum (50 dynes/ cm) by surface tension mirror

8.Thin layer chromatography and HPLC for dye contain and other subsidiary dye testing

9.Heavy metal test: Less than 20 ppm

DESALINATION IS CARRIED OUT AS UNDER

1.Distillation to remove inorganic component

2.Ultra-filtration for remove in organic impurities

3.Reverse Osmosis to make compound salt free

4.Ion exchange to improve solubility

5.Carbon treatment to improve Surface tension

6.Micro-filtration to remove all most 100% insoluble

7.Specialized cartridge filtration (o.5 micron) to remove most insoluble

8.Remove oil parts in dye intermediates for light fastness and heat fastness improve

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |

Not Given